Several cooling towers in parallel are often seen in the installation and use of the design plan. When selecting several refrigeration units and other refrigerated equipment, several cooling towers are generally selected in parallel. Or considering the volume of the cooling tower and the limited terrain, several cooling towers will be installed in parallel. The equipment standard of the open cooling tower stipulates that when selecting the main engine, it is necessary to ensure as much as possible to facilitate the change of the available load. However, at this time, it is very troublesome to connect the condenser, the water pump, and the cooling tower to each other.

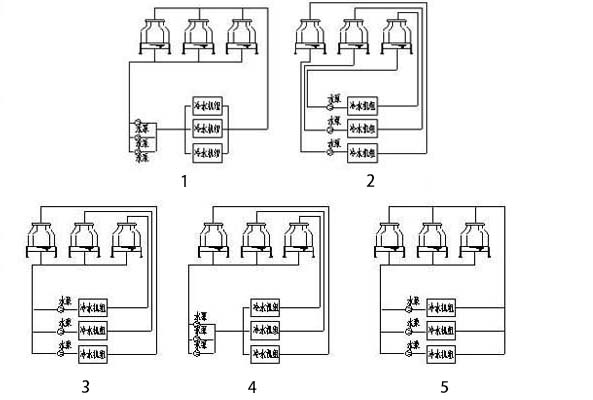

In engineering projects, when several cooling towers are operated in parallel, there are usually 5 piping methods, see Figure 1-5 above.

The layout of the pipeline in Figure 2 is the most complicated and occupies a large space, but the total flow adjustment is rationalized and the operation stability is high. The pipeline layout in Figure 1, 3, and 4 is simple, but overflow and water replenishment conditions often occur. The specific factors are:

1) Usually, an electric valve is installed on the inlet pipe of the cooling tower, but the outlet is not installed, and the inlet valve of the non-operation cooling tower is closed, but the outlet is connected. When a single unit is running, the water level of the cooling tower's water pan rises, causing overflow, while the water pans of other non-operating towers are constantly replenished.

2) The unbalanced adjustment of the water volume of each cooling tower is mainly due to the pipeline layout. Some cooling towers have low frictional resistance in the water inlet pipe and large frictional resistance in the water outlet; more water inflow and less water, causing overflow. Some towers turn the other way around, constantly replenishing water.

3) When several cooling towers with different cooling towers are connected in parallel, the water level in the towers will be different and the tower with the low water pan must overflow.

According to the above situation, when several cooling towers are set up in parallel, special attention should be paid to the balance, including the cooling tower balance pipe and water balance. Generally, the following types of countermeasures are used for the combined water inlet method:

1) According to Figure 1, the water inlet and outlet of each cooling tower are equipped with electric valves, and they are interlocked with the water pump and the cooling tower fan.

2) For Figures 1, 3, 4, the water level lines of the cooling towers (how many different towers are included) are operated at the same height, and the height difference should not be greater than 30mm. Install balance pipes in the middle of each tower, and increase the pipe diameter of the common pipe section of the water outlet.

3) According to Figures 1, 4, in order to balance the water volume of each chiller, a control valve can be installed at the outlet of each chiller.

4) The pipeline layout in Figure 5 is simple, and the total flow of equipment is also easy to balance. This method is generally used.

Cooling tower plays an important role in central air-conditioning equipment as a cooling device at the end. Reasonable equipment can be easily available, economical and reliable. If equipment is unscientific, it may cause huge waste. More serious, affect the regular operation of equipment, and cause serious adverse effects on production and life. This is the case for a single cooling tower. For several cooling towers in parallel, if the process design is unscientific, it may cause huge waste and affect production. Therefore, in the face of such a situation, we should deal with it carefully and choose a very reasonable method to equip the cooling tower balance pipe.

Article Address:https://www.trlen.com/baike/308.html

Guangdong Trlon Energy-saving Air Conditioning Equipment Co., Ltd.

Contact:Mr. Wang

Free Hotline:4008-8383-95

Company Email:sales@trlon.com

Web Site:https://www.trlen.com/

Company Address: 1916A, Block A, David Donglong Business Building, Longhua, Longhua District, Shenzhen