Industrial cooling tower noise noise treatment solution

Author:Trlon Views: Time:2020-11-09

With the development of industry, there are many occupational hazards in many industrial enterprises, among which noise hazards are particularly prominent. In order to reduce noise pollution to the surrounding environment, improve work efficiency, and maintain the health of producers, it is necessary to control the noise of cooling towers. Among the many noise sources, the noise of industrial cooling towers has always been a difficult point in noise management. This article introduces the noise treatment plan of industrial cooling tower through an engineering example of a certain unit, and conducts field tests.

1. Project Overview

A company has three existing industrial cooling towers, which are mainly used for the circulating use of the cooling water of the oxygen generator. The plane position is shown in Figure 1. Among them, 1# and 2# cooling towers are respectively composed of 3 cooling towers, a single cooling water volume is 500t/h, 3# cooling tower is composed of 4 cooling towers, a single cooling water volume is 900t/h, 1#, 2 #, 3# The total cooling water volume of the cooling tower is 6600t/h. The cooling tower adopts mechanical ventilation, and the fan is installed on the upper part of the cooling tower. On July 10, 2002, the relevant monitoring department measured the noise at the plant boundary. The monitoring results are: the noise at the plant boundary is 68.7dB(A) during the day and 62.3dB(A) at night. The "Noise Standards at the Boundary of Industrial Enterprises" (GB12348-90) stipulates that the noise in the industrial zone must meet the requirements of the Class III standard, that is, the noise at the factory boundary shall not exceed 65dB(A) during the day and 55dB(A) at night. According to this standard, the noise at the factory boundary of this unit exceeds the requirements of the national standard both day and night, so it needs to be controlled.

A8bCooling tower noise reduction treatment manufacturer

A8bCooling tower noise reduction treatment manufacturerCooling tower plan location map

2. Analysis of main noise sources

The noise generated by the cooling tower during normal operation includes splashing water noise, fan noise, motor noise, circulating water pump noise, and water pipeline vibration radiation noise. Among them, the splashing noise of the cooling tower, fan noise, and motor noise are the main noise sources.

2.1 Splash noise

Water splash noise is produced by two different noise mechanisms: one is the sharp impulse noise emitted when a water drop hits the water surface; the other is the noise radiated by the volume pulsation of the bubble generated by the water drop.A8bCooling tower noise reduction treatment manufacturer

Because the cooling tower has a strong sound insulation capacity, the splashing noise radiated from the tower body is negligible, and only the splashing noise radiated from the air inlet needs to be considered. Due to the high drop height of the cooling tower, the splash speed and kinetic energy of the water droplets are high, which results in high splash noise. Measured at 1m away from the air inlet, the noise is 83.2dB(A). It is worth noting that the air inlet area of the cooling tower is very large, the air inlet area of each side of the 1# and 2# cooling towers is 70.2m2, and the air inlet area of each side of the 3# cooling tower is 93.6m2, and the splashing noise is in the direction of surface sound source. External radiation, noise attenuates with the increase of the propagation distance, splashing water noise becomes the main noise source of noise at the factory boundary.

2.2 Fan noise

Fan noise is aerodynamic noise, including rotating noise and turbulence noise. Rotational noise is the gas pressure pulsation noise caused by periodic blows to the air when the fan blades rotate; turbulence noise is mainly the noise generated by the air attached to the blades continuously slipping into vortices when the fan blades rotate. The fan noise of the cooling tower is mainly turbulence noise.A8bCooling tower noise reduction treatment manufacturer

Because the diameter of the fan impeller of the cooling tower of this project is greater than 4m, the linear velocity of the fan impeller tip is relatively large, so the noise is relatively large. Due to conditions, the on-site measurement could not be carried out (the measurement needs to be carried out at 45° above the cooling tower fan). Estimated according to relevant experience, the noise should be around 86dB(A). Fan noise presents low frequency characteristics, and the airflow moisture content is high, which makes it difficult to manage. In addition, the cooling tower fan is located on the top of the cooling tower, and the noise of the fan has a greater impact on the noise in the distance than in the vicinity. Therefore, the main sensation around the cooling tower is water splashing noise, but it cannot be judged from this that the cooling tower fan noise has no effect on the noise of the factory boundary, and the degree of its influence needs further measurement and analysis.

2.3 Motor noise

Both fans and pumps need to be equipped with motors. Motor noise mainly includes rotating noise caused by poor dynamic balance of the rotor, electromagnetic noise caused by the cutting magnetic field of the rotor, aerodynamic noise of the cooling fan, and mechanical noise caused by bearing friction.A8bCooling tower noise reduction treatment manufacturer

The motor of the fan is installed in the open air on the top of the tower, and the noise measured 1m away from it is 73.2dB(A). After other noise sources are treated, the noise of the motor will have a certain impact on the noise of the factory boundary at night, and further treatment is needed.

3. Noise control plan and implementation

According to the analysis of the current monitoring data of the unit’s noise, and after economic and technical comparison, it was decided to adopt a noise control plan of "one-time design, gradually implemented".

3.1 Controlling the splashing noise of cooling tower affecting the northern section of the plant boundary

(1) A three-layer silencing pad is arranged in the space above the water collection tray on the side of the 3# cooling tower adjacent to the plant boundary. The muffler pad should meet the requirements of not only effectively reducing splashing noise, but also not hindering the water cooling effect, and being durable in use and easy to replace.A8bCooling tower noise reduction treatment manufacturer

(2) A three-layer silencing pad is arranged in the space above the water collecting pan on the north side of the two units on the east side of the 2# cooling tower.A8bCooling tower noise reduction treatment manufacturer

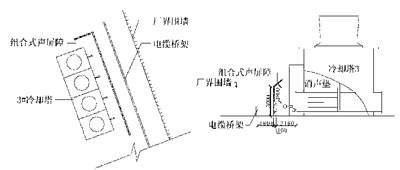

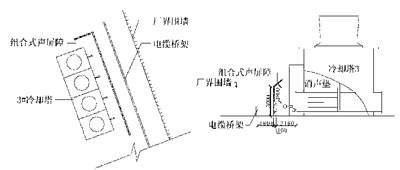

(3) Install a combined sound insulation barrier on the side of the 3# cooling tower and the 2# cooling tower adjacent to the factory boundary. The position of the sound barrier is shown in Figure 2. The lower part of the barrier is silencing louvers to facilitate the air intake and ensure the cooling needs of the circulating water. The silencing shutters should have good weather resistance due to outdoor use. In addition, in order to ensure the air intake and reduce the air resistance, the silencing louvers should have sufficient ventilation area and reasonable shape. The upper part of the sound barrier is made into a "Γ" shape to reduce the height of the barrier. Sound-absorbing materials are attached to the barrier to further improve the sound insulation effect. In addition to the need for noise reduction, the installation of sound barriers should also take into account the daily management and maintenance of the cooling tower and adjacent cable trays.

A8bCooling tower noise reduction treatment manufacturer

A8bCooling tower noise reduction treatment manufacturerInstallation location diagram of cooling tower sound barrier

3.2 Controlling the impact of 1# and 2# cooling tower splashing noise on the southern section of the plant boundary

(1) A three-layer silencing pad is arranged in the space above the four water collecting pans in the two units on the east side of the 1# cooling tower.A8bCooling tower noise reduction treatment manufacturer

(2) A three-layer silencing pad is arranged in the space above the water collecting pan on the south side of the two units on the east side of the 2# cooling tower.A8bCooling tower noise reduction treatment manufacturer

(3) Add a combined sound barrier on the side adjacent to the factory boundary.

3.3 Control other noise sources of cooling tower

(1) Arrange two silencing pads in the space above the remaining eight water collecting pans of cooling towers 1#, 2#, and 3#.A8bCooling tower noise reduction treatment manufacturer

(2) Add piece-type resistive muffler to ten fans in 1#, 2# and 3# cooling towers. As the noise reduction requirements are not high, the design height of the muffler is 1.2m.A8bCooling tower noise reduction treatment manufacturer

(3) is equipped with a semi-sound insulation cover for the motor of the fan.

4. Cooling tower noise control effect

After taking the above control measures, the cooling tower noise can be effectively controlled. The test results show that the noise index of the plant boundary has been controlled within the national standard, which reduces the noise pollution of the cooling tower to the plant area. The noise control of cooling towers shows that the splashing noise of industrial cooling towers should be the focus of noise control.

Article Address:https://www.trlen.com/news/211.html