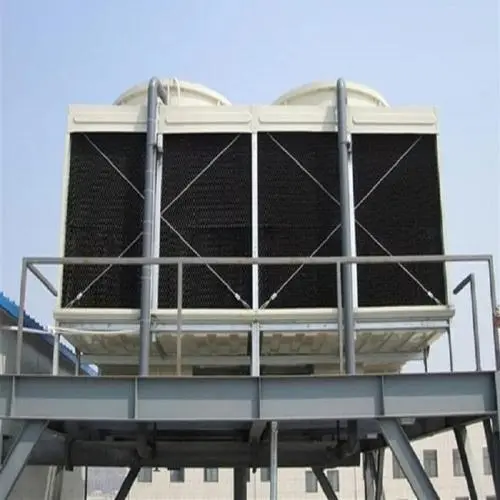

(1). The so-called cooling tower is an evaporative heat dissipation device that uses water as a circulating coolant to dissipate the waste heat generated in the industry or in refrigeration and air conditioning to reduce the water temperature to ensure the normal operation of the equipment series, which means that the cooling effect is good. Bad is very important! But how much do you know about the reason for the poor cooling effect of the cooling tower? In the process of using it, how can we deal with the cooling effect?

(2) Energy-saving cooling tower, as an indispensable equipment for circulating water to cool down, has brought huge energy-saving effects to users in the industrial and civil fields, protecting the waste of water resources, and achieving energy-saving and emission-reduction effects. There are many problems. For example, we use a cooling tower to achieve a cooling effect, but factors such as heat sinks, fan air volume, cooling tower water usage, and device orientation may have a certain influence on the cooling effect. Among them, the heat sink and the air volume of the fan have the greatest impact on it, and the main manifestations are:

1. Heat sink: It is the key component of the cooling tower. Small towers generally use PVC sheet hot pressing or thermal suction type, and large towers will use wood. The primary intention is to make the contact surface of air and water without affecting the wind resistance, the bigger the better. At the same time, the heat exchange rate also reaches the maximum. The two parameters of the heat sink affecting heat transfer are the shape and height of the heat sink. In the water tower installation, try not to damage the heat sink to avoid poor water flow on the heat sink;

2. Fan air volume: It mainly speeds up the air flow in the tower, speeds up the heat exchange between air and water, and takes away heat. The main influence on the air volume of the fan is the shape of the blade, that is, the width and length of the blade and its own deflection angle, the speed of the blade, the angle of the device, the speed and the motor and transmission ratio. In addition, when the air volume is certain, the cooling effect of the same type of tower with a small cooling water volume is better than a large cooling water volume.

Note: As long as we pay attention to these two issues during acquisition, installation and protection, I believe it will not be a big problem.

Other reasons why the cooling tower's cooling effect is not considered are:

1. In the long-term use of the cooling tower, because the circulating water is dirty and hard, the filler is soaked in the water with a relatively high temperature for a long time, resulting in the phenomenon of scaling and blocking of the filler, long-term accumulation, and the texture of the filler is Obstruction, so the cooling effect is not up to standard;

2. It is caused by improper selection of cooling towers. Because the cooling towers are not matched according to their own flow rate and inlet water temperature, standard cooling towers are used as industrial cooling towers, small horse-drawn carts, so the cooling effect must be no;

3. The airtightness around the cooling tower is too good, the ventilation type is too poor, and the air cannot circulate, so the cooling effect of the glass fiber reinforced plastic cooling tower is not good.

(3) Detailed handling method:

1. Regarding the first point, the cooling tower packing can be replaced;

2. It can reduce the inlet water flow rate of the cooling tower, and halve the flow rate based on the original flow rate to reduce the temperature.

(4) So far, the fans used in industrial cooling tower cooling are all driven by electric motors. The electric energy consumed by these motors in a year is very large. Take a cooling tower with a cooling water volume of about 1,000 tons/hour as an example: the power of the motor is about 45 kilowatts. It operates 24 hours a day and operates 300 days a year. The annual electricity consumption is about 324,000 kilowatt-hours. For the tens of thousands of cooling towers across the country, the electricity consumption costs of the motors equipped are quite staggering. How can the power consumption of the cooling tower be drastically reduced? It is the most important energy-saving problem that enterprises need to deal with at present. Aiming at the energy saving of the complex system, after in-depth research and years of engineering practical experience, a new type of water turbine is finally selected as the power source of the cooling tower fan instead of the electric motor, and then the energy saving effect is achieved!

(5) In detail, the excess energy in the circulating water system is used to propel the water turbine to roll, thereby driving the fan to rotate. The water turbine replaces the electric motor, achieving zero power consumption and fundamentally saving energy. It is understood that the current manufacturing standards of the cooling tower industry are more concerned with the safety and reliability of the cooling tower. Therefore, there is a surplus in the cooling tower's air-to-water ratio, water distribution area, filling area, water spray density, pump flow and head, piping system and valves, fan air volume and power and other parameters, and the remaining air volume, water volume and head It was ruined in vain and consumed a lot of energy. Use the turbocharged water wheel technology, use the original circulating cooling tower water of the cooling tower equipment to promote the fan to dissipate heat, abolish the traditional cooling tower top using a motor-driven fan to dissipate heat, eliminate the mechanical deceleration device and the motor, and then complete the "0" electrical energy Consumption of new energy-saving and environmentally-friendly cooling towers. Moreover, the residual pressure of circulating cooling water is used to drive the cooling tower fan, which has a significant effect of energy saving and consumption reduction. The development and application of this turbine is also in full compliance with the national energy saving and emission reduction policy, and it has a wide range of applications.

Article Address:https://www.trlen.com/news/512.html

Guangdong Trlon Energy-saving Air Conditioning Equipment Co., Ltd.

Contact:Mr. Wang

Free Hotline:4008-8383-95

Company Email:sales@trlon.com

Web Site:https://www.trlen.com/

Company Address: 1916A, Block A, David Donglong Business Building, Longhua, Longhua District, Shenzhen