How to perform efficient maintenance on closed cooling towers High quality wall spraying repair of closed cooling towers is a necessary and effective measure to maintain the lifespan of the tower. The overhaul cycle for low-quality spraying in cold regions is only 2-3 years, while the overhaul cycle for high-quality spraying can reach 10 years. Improving

What are the five major performance indicators of a water turbine cooling tower? A water turbine cooling tower is a device that utilizes the contact between water and air to evaporate and dissipate waste heat generated in industry or refrigeration and air conditioning. For industrial production, without cooling towers, it is impossible to carry out produc

At present, most closed cooling towers on the market use materials that are not easily corroded or damaged, such as galvanized steel plates and fiberglass. The coolant also flows in the enclosed copper tube. In theory, it won't leak, but why do people always respond by saying their cooling tower is leaking? There may be many reasons for water leak

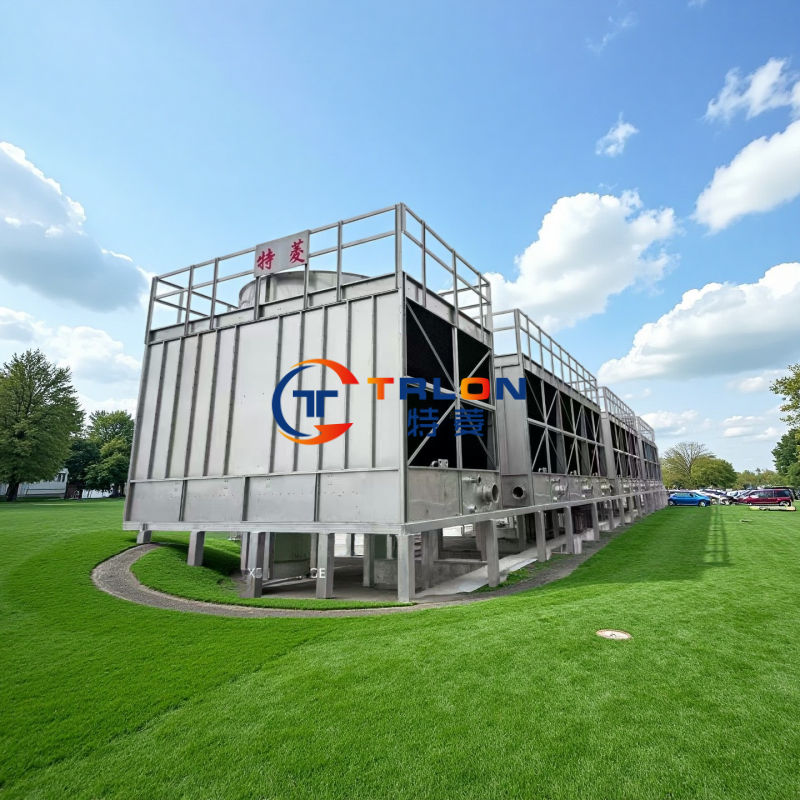

The closed cooling tower adopts a closed circulation system to process the liquid with residual heat energy engineering, achieving the actual refrigeration effect of the liquid and flowing gas in the closed circulation system. Compared with open cooling towers, cooling towers have the characteristics of good thermal performance, high processing quality, an

The circulating water tank of a closed cooling tower is determined by the operating mode of its equipment. Its materials are mostly stainless steel and a small amount of FRP materials, which have equipment operation stability and good pressure resistance and corrosion resistance. The box of the circulating water tank is basically square. In terms of shape,

Cooling towers are divided into open cooling towers and closed cooling towers, but what is the difference between the two? Let's take a look. 1、 Operating principle Operating principle of closed cooling tower: Closed cooling tower uses the principle of absorbing heat during water evaporation to cool the cooled liquid. Spray water (cooling water)

The correct operation method of cooling tower Although the cooling tower is an accessory equipment in the air conditioning refrigeration system, it plays an important role in dissipating the total heat absorbed by the entire system. Therefore, the correct operation of the cooling tower directly affects the cooling effect and energy saving of the entire ai

Scope of application of cooling tower The waste heat generated in industrial production or refrigeration processes is generally guided away by cooling water. The function of a cooling tower is to exchange heat between the cooling water carrying waste heat and the air inside the tower, transferring the waste heat to the air and dissipating it into the atmo

Working principle, installation, selection and fault analysis of cooling tower Basic Principles of Cooling Tower Operation 1. Basic Principles of Cooling Tower Operation Dry (low enthalpy) air is drawn by a fan and enters the cooling tower through the air intake network; High temperature water molecules with high partial pressure of saturated steam flow

Precautions for Cooling Tower Design and Selection Regarding the location setting: 1. The cooling tower should be installed in a clean and well ventilated environment, and a certain distance should be maintained during the installation of the tower group to ensure that it meets the design requirements for air volume. 2. Cooling towers should be installe

Guangdong Trlon Energy-saving Air Conditioning Equipment Co., Ltd.

Contact:Mr. Wang

Free Hotline:4008-8383-95

Company Email:sales@trlon.com

Web Site:https://www.trlen.com/

Company Address: 1916A, Block A, David Donglong Business Building, Longhua, Longhua District, Shenzhen