Installation site selection and precautions for closed cooling towers

Closed cooling towers should be installed on roofs or buildings or floors with sufficient load-bearing capacity, requiring good ventilation to ensure exhaust; The distance between the air inlet of the cooling tower and the building wall should not be less than 1.5-3 times the diameter of the tower body to meet the requirement of non blockage. Dry and cold air ions enter the tower, effectively avoiding the generation of hot air. Cooling towers should be avoided from being installed in waterproof channels or high walls with poor air circulation.

Avoid installing closed cooling towers in areas with high levels of smoke and dust pollution, to prevent smoke and dust from blocking the membrane, and to avoid places with excessive acidic emissions, explosive dust, severe smoke and water vapor. At the same time, it should be kept away from high-temperature environments such as kitchens or boiler rooms to ensure the performance of entering cold air and dissipating heat.

When installing a closed cooling tower, the tower should be as horizontal as possible and not tilted. The centerline of the cooling tower should be perpendicular to the horizontal plane, otherwise it will affect the motor. Due to the inability of the tower to withstand water when the water pipes are full, independent pillars need to be installed to transport the water pipes; When installing the chassis, the staff should step on the reinforcement strip of the chassis to avoid trampling on it; When installing the casing, the chassis should avoid deformation. After confirming that the chassis is not deformed and the surrounding joints are dry, fiber wool and coating resin should be placed at the joints before laying to avoid leaking tower bodies.

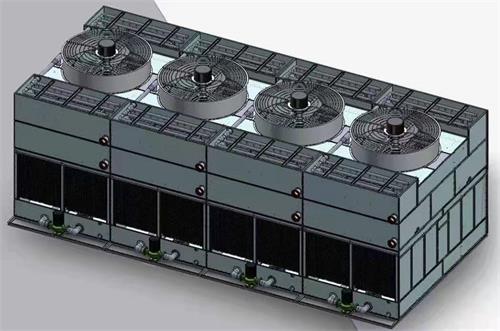

The fan of a closed cooling tower should rotate clockwise, with the wind direction pointing upwards or outwards. The gap between the tip of the fan and the tower wall should be uniform. Check whether the blade installation angle is the same, whether the debugging operation is balanced, and whether the power supply is consistent with the rated power. The motor should be wired according to the marked wiring direction. After wiring, the junction box should be sealed. The motor circuit should have phase loss protection and overload protection to ensure reliable operation of the motor.

Closed cooling tower pipelines and pump valves should be installed below the operating water level to prevent overflow and air intake; When considering the location of equipment, sufficient pump heads, pressure losses along the way, and pressure losses of cooling coils should be taken into account; The pressure of the liquid cooling interface flange should be designed to be 1Mpa, and all pipelines should be considered for suspension or support.

With professional experience in the research and development of cooling equipment and production technology, combined with advanced management concepts at home and abroad, the company has formed a first-class R&D team. The company mainly produces process water cooling and gas condensation equipment such as closed cooling towers, evaporative condensers, and open cooling towers. At the same time, it can also customize products that best meet customer requirements according to their different needs. At present, various types of cooling equipment produced by our company have been widely used in thermoelectric, chemical, textile, electronic metallurgy, pharmaceuticals, cigarettes, scientific research institutions, hotels, shopping malls, cinemas, civil buildings, and air conditioning refrigeration cycle water cooling projects. Welcome new and old customers to consult and negotiate cooperation!

Article Address:https://www.trlen.com/news/738.html

Guangdong Trlon Energy-saving Air Conditioning Equipment Co., Ltd.

Contact:Mr. Wang

Free Hotline:4008-8383-95

Company Email:sales@trlon.com

Web Site:https://www.trlen.com/

Company Address: 1916A, Block A, David Donglong Business Building, Longhua, Longhua District, Shenzhen